Talk to an expert

For more information or to request a Brochure, call us on 02392 590 281

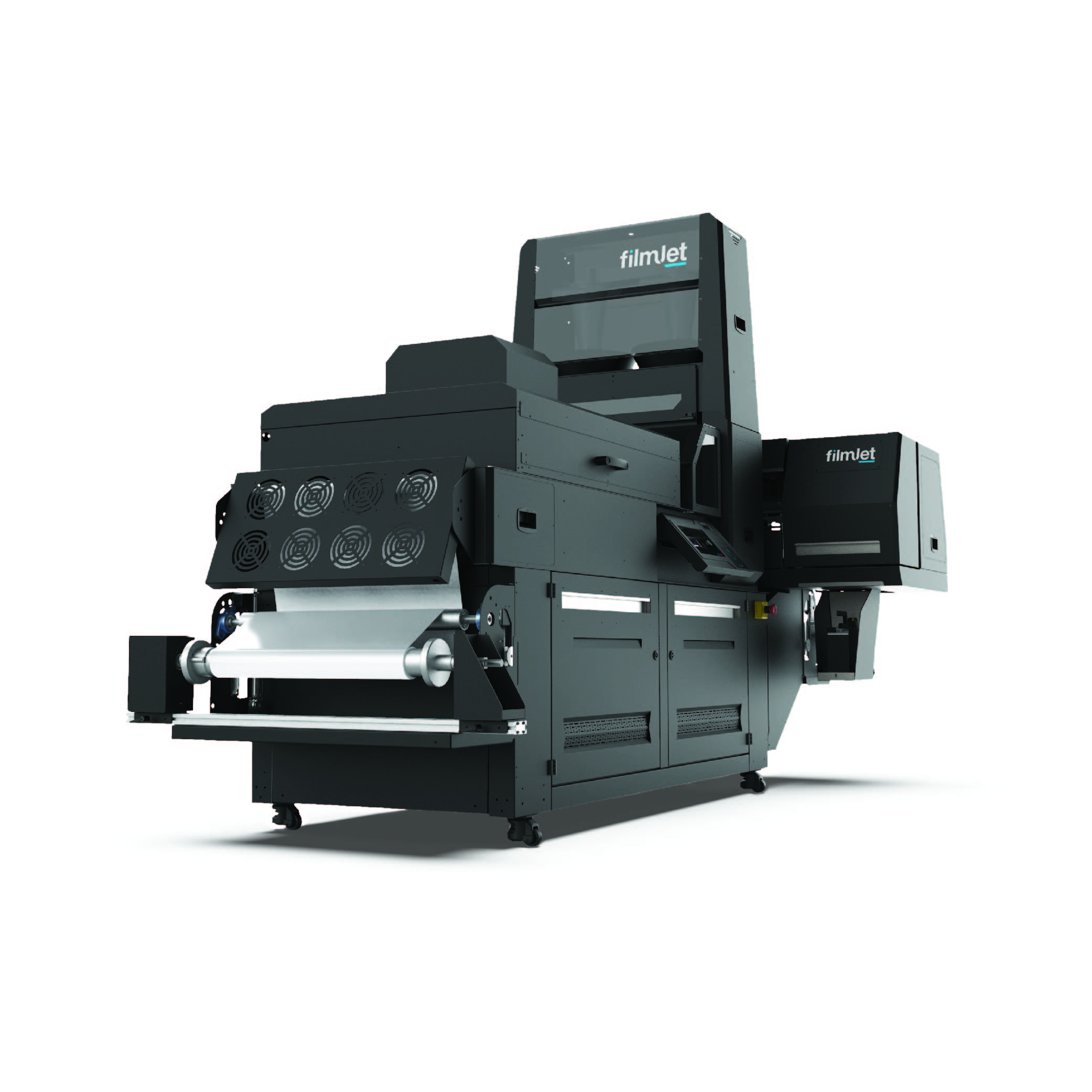

Adkins Pro Cure Oven

£1,495.00 +VAT (£1,794.00 inc VAT)

The Adkins DTF Pro Cure Oven is a versatile, high-performance solution designed for efficient and reliable DTF transfer curing. Featuring dual 62 x 42 cm reciprocating trays, it allows continuous production—cure in one tray while loading the other—maximizing workflow efficiency. Compatible with both sheet-fed and roll-fed DTF printers, it easily adapts to various production setups.

Its compact desktop design fits perfectly on standard 600mm deep worktops, making it ideal for any workspace. The integrated filtration and extraction system ensures a safer, cleaner working environment by removing fumes and particles during operation.

Control is effortless with the intuitive digital touchscreen, offering clear parameter settings and explanations for precise, user-friendly operation. Powered by a fan-assisted heat circulation system and 10 curing elements, the Pro Cure Oven delivers fast, consistent results—perfect for high-volume production.

A dependable, space-saving solution for any professional DTF printing setup.

- Description

- Specifications

Description

The Perfect Versatile Curing Solution for Efficient High and Low Volume DTF Production

Experience fast, efficient, and hassle-free curing with this advanced cure oven, designed to meet the demands of high-volume DTF production. Powered by a highly effective fan-assisted heat circulation system and equipped with 10 curing elements, it delivers rapid and consistent curing results every time.

The automatic operating mode seamlessly rotates the trays without the need for manual handling, maximizing productivity and minimizing downtime. With two spacious 62 x 42 cm trays, the oven easily accommodates two A3 sheets side by side or larger formats from roll-fed printers, offering flexibility for various production needs.

An integrated extraction system with easily accessible removable filters ensures a clean and efficient workspace. Combining versatility, reliability, and performance, this cure oven is the ideal solution for any professional DTF printing setup.

- Dual Drawers – Two 62 x 42 cm reciprocating trays enable continuous workflow by allowing users to cure in one tray while simultaneously loading the other to maximise efficiency

- Compatible with Roll-Fed and Sheet-Fed Printers – Designed for versatility, this machine is ideal for both DTF sheet-fed and roll-fed printer users, seamlessly accommodating a variety of printing setups and production needs.

- Compact Desktop Design – Engineered with a 600mm depth to fit perfectly on standard worktops, making it ideal for space-conscious workspaces without compromising functionality.

- Built-In Filtration and Extraction System – Ensures safer operation by effectively removing fumes and particles, promoting a cleaner and healthier working environment.

- Intuitive Digital Touchscreen – Easy-to-use interface with clear parameter explanations, allowing for effortless control and precise adjustments to streamline operation.

- Robust Construction – Built with the heavy-duty quality you expect from Adkins, this machine offers durability and reliability for long-term, demanding use.

- Consistent Heating – Featuring 10 heating elements, this system delivers uniform and efficient curing, ensuring reliable results across every job.

- No Special Power Requirements – Easily plugs into a standard 13-amp socket, eliminating the need for specialised electrical installations and allowing for quick, hassle-free setup in any workspace.

Dual reciprocating drawers

Equipped with advanced low powder sensors and clearly visible warning lights, this system continuously monitors powder levels in real-time. Operators are instantly alerted when refills are needed, allowing for proactive maintenance. This helps to prevent unexpected downtime, maintain consistent production flow, and ensure optimal performance throughout every job.

Integrated filtration and extraction

Designed to actively capture and remove airborne particles, fumes, and dust generated during operation, this advanced system helps maintain a cleaner, healthier working environment. By improving air quality and reducing exposure to potentially harmful substances, it not only enhances operator safety but also supports compliance with workplace health standards. The efficient filtration and extraction system ensures continuous, worry-free operation, making it ideal for busy production settings.

No special power requirements

Why Amaya?

Don’t just take our word for it.

Any company can sell a product, that is the easy bit. Amaya takes it to the next level, firstly with their due diligence, they will only sell you a product that is suitable for your business. Once you have the product the after sales service is something else. Combining on site product training on installation with continual free training days with industry specialists. I could not recommend Amaya enough for your next purchase to enhance your garment decoration business.

Always on hand with the best products and advice to grow, maintain and prosper with our printing and embroidery business. Their friendly service and prompt flexible attitude makes them second to none. If I could keep them a secret I would – I do not hesitate in recommending everyone at Amaya Sales UK.

Have used Amaya since 2003. Seventeen years !!! sheesh lol. They helped my business from day 1 and i am still running. Julian and co have been supportive throughout. We have exchanged several bottles of champers over the years as our families have grown. If you are seriously considering entering this business then i would highly highly recommend. You are not just buying a piece of machinery. You are buying a caring, rich in experience support network.

Amaya Uk have been beside us as a Company for over 17 years, and through that time they have always been there to offer advice and help. Through their excellent support we have grown not just in the world of Embroidery, but in printing through the various printing formats they offer. We have found them professional, caring and helpful, and always willing to go that extra mile to ensure we have what we want, not what they want. We can only thank them for all their help, and just wish we met them a lot earlier.

| Power Consumption | 2.6KW (Heat Up) / 2.2KW (Operating) |

| Power supply | 220-240 Volts AC |

| Socket Requirement: | Removeable Standard Domestic Plug – UK-13A |

| Circuit Breaker: | 15A |

| Weight | 94KG |

| Machine Size: | 86(w) x 55(h) x 67(d) cm |

| Front Foot to Rear of Machine: | 53 cm |

| Package Size: | 93(w) x 60(h) x 73(d) cm |

| Suggested Minimum Workable Area: | 101(w) x 70(h) x 110(d) cm |

| Max Tray Size: | 62(w) x 42(d) cm |

| Heating: | 5 x Top / 5 x Bottom Elements |

| Heating Temperature: | Max 140 degrees |

| Heat Up Time: | Approx 7mins (120 degrees) |

| Air Purifier: | In-built filtration and extraction system |

| Oil Removal: | Sealed Oil Collection and Drainage Tap |

Recently Viewed

For more information or to request a Brochure, call us on 02392 590 281